Servo MITSUBISHI JE DRIVE

MR-JE family of products leverages advanced functionality such as true one-touch auto-tuning, vibration suppression, and machine diagnosis functionality in an easy-to-use servo solution.

MR-JE-A Cost Competitive Servo

The MR-JE servo and compatible HG-KN and HG-SN motors provide a user friendly, high quality, low-cost servo solution. Leading edge technology and advanced functionality packed into this servo solution easily tackle common problems such as high software acquisition costs, noise issues, poor settling times, cumulative positioning errors, unpredictable mechanical component failure and much more. The MR-JE is a cost competitive solution ideal for packaging, labelling, pick and place machines, and much more.

Key Benefits

- Advanced One-Touch Auto-Tuning™ – For peak performance that really works

- Built-in positioning function – Easy to use programming interfaces (point table/program/indexing modes available)

- Advanced Vibration Suppression Control II™ – Automatically suppress machine resonances and extend machine life

- Large capacity drive recorder – Reduce troubleshooting time

- High quality and reliability of the Mitsubishi Electric brand – Increased machine uptime

- Modbus® RTU Connectivity and Modbus-RTU Communication – Easily control or monitor the servo by external master/slave device

- High 18-Bit Resolution Encoder – Achieve High-Accuracy Positioning

Outstanding Performance

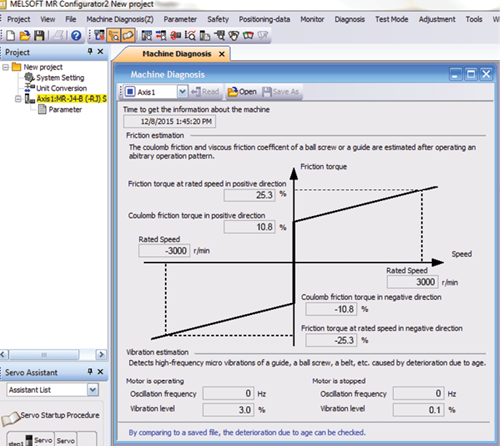

Machine diagnosis function adds an easy to use tool to your proactive maintenance plan

- Improves machine efficiency – Mitsubishi Electric provides powerful first-class advanced One-touch Auto‑tuning that sets gains and filters in real-time. Over the life cycle of the machine continuous tuning optimizes gains to minimize settling time and eliminate cumulative errors. As the machine ages, system longevity and machine efficiency are improved.

- Simple to understand and setup – Built-in positioning function allows positioning systems to be configured without a positioning module to simplify system cost and bill of material. Users can select the preferred style of programming from 3 easy to use methods; point table (31 points), program (Up to 480 Steps, 256 programs) and indexing (up to 255 stations).

Applications requiring camming will benefit from the simple cam function, which makes it easy to enable synchronous control with 3 different cam control modes. Control via software rather than mechanical components reduces maintenance and commissioning time, and increases machine flexibility.