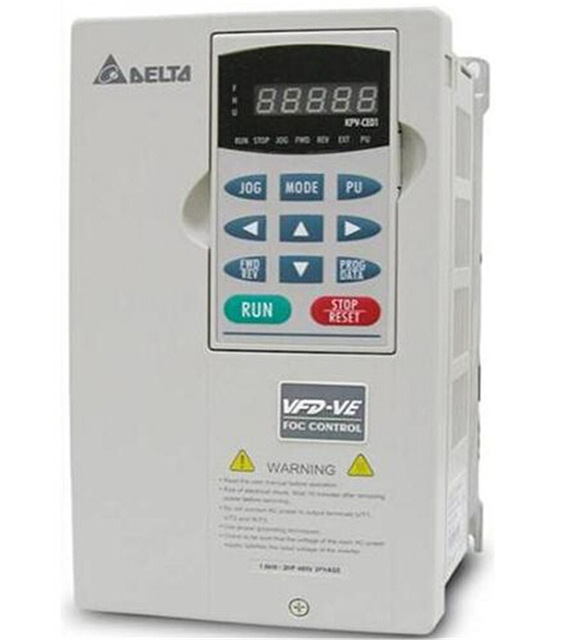

Inverter DELTA VE/VL/VJ SERIES

Features

This series adopts FOC (Field Oriented Control) which is a far more precise vector control algorithm. It can be used in both speed control and position control similar to a servo motor drive. The multi-function I/O terminal is expanded to meet users' various application needs. In addition, it is supplied with a Windows based PC software program for managing parameters and dynamic monitoring. It provides an excellent solution for load regulation. It can output 150% of rated torque at zero speed, and it can have "point to point" and relative distance control functions for position control, making it the best choice for challenging industrial control applications.

Specifications

-

Output frequency: 0~600Hz

-

4 points adjustable V/F curve, Sensorless Vector Control, Field-Oriented Control

-

Position/Speed/Torque control mode

-

Sensorless Vector Control 150% torque at 0.5Hz

-

150% holding torque with speed feedback

-

Overload : 150% for minute and 200% for 2 seconds

-

Rotational/Static Auto-tuning for the motor parameters and Auto-tuning for load inertia

-

Excellence torque limit in all 4 quadrants of operation

-

Dual RS-485 ports, Fieldbus and PC software tools for applications

Applications

Power transmission equipment, elevator, crane, CNC tooling machines, extrusion machines, injection molding machines, and auto-storage and retrieval systems.

VFD-VL Series

Delta's VFD-VL series AC motor drive designed for elevators are based on years' of experiences in designing AC motor drives, and the latest control technology adopted in VFD-VL will offer you high reliability and safety. All the features of VFD-VL are to meet the needs from the market, e.g. controlling the brake for motors, backup electricity, built-in brake loop, auto-tuning of motor parameters, numerous encoder interfaces, bountiful communication functions and self protection, etc.

-

Output frequency: 0.00 ~ 120.00Hz, offering output torque of more than 150% when at zero speed.

-

The vector control by FOC, enabling smooth and comfortable operation of the elevator.

-

S-curve acceleration/deceleration and battery for abnormal power shut-down.

-

Overload capacity: 150% of rated current for 1 minute and 200% of rated current for 10 seconds

-

Complied with EN954-1 (safety-relay) standard.

-

The built-in brake module saves you installation space and cost

-

Built-in with Modbus/CAN bus communication interface.

-

With optional LCD digital keypad and PC tuning software.

Home elevator, cargo elevator, passenger elevator, residential elevator and crane.

VFD-VJ Series

The Delta Hybrid Servo Drive VFD-VJ Series is designed with AC servo technology to drive hydraulic systems with perfect control of the drive, motor and hydraulic unit.

Specifications

- Field Oriented Control

- Suitable for both synchronous servo motors and asynchronous servo motors

- Built-in brake unit (up to 22kW)

- RS-485 communication interface (RJ-45) and standard MODBUS communication protocol

- Precise current detection for system protection with safety ensured

- New software for PC connection allows real time monitoring of AC motor drive status

Structure of a Hybrid Servo System

- When pressure and flow instructions are given to the injection molding machine, the Delta VFD-VJ series begins PID calculation simultaneously to attain the actual pressure and speed feedback data, and drive the servo motor and the hydraulic pump. The Delta VFD-VJ series offers you a system with fast response and high duplication accuracy.

Inverter DELTA REG/AFE/M SERIES

Sensorless Vector Micro AC Drive. The compact design is ideal for small and medium horsepower applications. The M drive is designed to provide an ultra-low-noise operation, and includes several innovative technologies that reduce interference.

-

Output frequency 0.1 ~ 400 Hz

-

Adjustable V/f curve and vector control

-

Carrier frequency up to 15 kHz

-

Auto torque boost & slip compensation

-

Built-in PID feedback control

-

Built-in MODBUS communication, baud rate up to 38400 bps

-

0 speed holding function

-

Built-in sleep / revival function

-

Support communication module (DN-02, LN-01, PD-01)

Applications

Packing machine; dumpling machine; treadmill; temperature/humidity control fan for agriculture and aquaculture; mixer for food processing; grinding machine; drilling machine; small size hydraulic lathe; elevator; coating equipment; small size milling machine; robot arm of injection machine (clamp); wood machine (two-side woodworking planer); edge bending machine, elasticizer, etc.

REG2000 Series

A traditional drive system used for inertia load work generally performs rapid deceleration, braking and positioning. When its motor is in generator mode it produces large amounts of regenerative energy that must be consumed to maintain a stable DC bus voltage and safe operation. The traditional method to solve the regenerative energy problem is to install a brake resistor. While it is easy to install and is low cost, it takes up a large amount of space and requires installing additional devices to dissipate the heat. This method provides limited efficiency and wastes the regenerative energy.

Delta's REG2000 series is capable of collecting and converting your system's regenerative energy into reusable electricity for the ultimate in energy savings. The installation process is as simple as installing a brake resistor, but with only half the size and better efficiency. The REG2000 is your best green energy solution for power regeneration.

-

Improves drive brake torque 125% to 150%

-

MODBUS 485 communication to real-time monitor kWh and cost

-

High flexibility, compatible with other inverters and servo drives

-

Parallel connections* for large power applications

-

More option cards* available upon purchase: MODBUS TCP, CANopen (DS301), PROFIBUS, DeviceNet, EtherNet/IP

-

* Please contact Delta Industrial Automation

-

Large-inertia load applications:centrifuge equipment, industrial laundries, roving machines and more.

-

4-quadrant load applications: elevators, cranes, pumpjacks and more.

-

Quick braking applications: machine tools, bag making machines, auto storage and retrieval systems, press machines and more.

-

Long-term energy feedback applications: printing machines, escalators and more.

Inverter DELTA B SERIES

Features

Sensorless Open and Closed Loop Vector AC Drive. The VFD-B series represents Delta's NEMA1 general purpose AC drive. The VFD-B series drive is rated to provide constant torque, featuring open and closed loop vector control. Delta offers an optional 2000 Hz high speed output that can be factory programmed at the customer's request.

Specifications

-

Output frequency 0.1 ~ 400 Hz

-

Adjustable V/f curve and vector control

-

Master/Auxiliary and 1st / 2nd frequency source selectable

-

16-step speed control and 15-step preset speed process control

-

Built-in PID feedback control

-

Auto torque boost & slip compensation

-

Built-in MODBUS communication, baud rate up to 38400 bps

-

Support communication module (DN-02, LN-01, PD-01)

Applications

Air conditioners for large buildings; woodcarving machine; punching machine; wastewater treatment systems; crane drive and swivel; washing machine; vertical stamping machines; compressor; elevator; escalator; circular loom; flat knitting machine; pasta machine; four-sided woodworking planer, etc

Inverter DELTA E/L/EL SERIES

Sensorless Vector AC Micro Drive. The VFD-E series represent Delta Electronics low horsepower, constant torque, IP20 rated Drive. Modular in design with flexible extension cards and a built-in PLC function, the E drive offers the ability to write and to execute simple Ladder Logic programs. This state-of-the-art series meets a full range of application requirements.

Specifications

-

Output frequency: 0.1~600Hz

-

Modular & compact design

-

Built-in PLC function

-

Built-in EMI filter (230V 1 phase / 460V 3 phase)

-

Optional Fieldbus Modules (DeviceNet, Profibus, LonWorks and CANopen)

-

RFI-switch for mains

-

Easy DC BUS sharing

-

Flexible extension

-

Complete Protection

VFD-L Series

Features

Sub-fractional low cost AC Drive. Specifically designed for low horsepower applications with built-in EMI filter to efficiently reduce electromagnetic interference and to conform to the CE EMI directive.

-

Output frequency 1.0 ~ 400Hz

-

Adjustable V/f curve

-

Carrier frequency up to 10 kHz

-

Auto torque boost and slip compensation

-

Build-in MODBUS communication, baud rate up to 9600 bps

-

Built-in EMI filter

Applications

Simple wood cutting, conveyer belt, wire drawing machine, etc.

VFD-EL Series

The VFD-EL series is multiple function new generation micro type AC drive. It has built in EMI filter, RFI switch, easy DC bus sharing for side-by-side installation, high precision current detection, overload protection, and a built In keypad.

Specifications

-

Output frequency: 0.1 ~ 600Hz

-

3 points adjustable V/f curve

-

Built-in PID feedback control

-

RFI-switch for IT mains

-

Built-in EMI filter (for models 230V 1-phase and 460V 3-phase)

-

Use RS-485 communication interface (RJ-45) with Modbus protocol

-

Optional communication modules for multiple communication protocols, such as Profibus, DeviceNet, LonWorks and CANopen

-

Complete protection function

Inverter OMRON RX

Customised to your machine

Omron realises that you need quality and reliability, plus the ability to easily and quickly customise your inverter to the application in hand. And with the RX, you have the perfect tool for the job. Naturally it combines the same high level of quality and performance for which Omron is renowned. It also has abundant application functionality on board and you can customise it yourself to match your precise requirements.

- Ratings up to 132 kW

- Full torque at 0 Hz in closed loop

- Sensor-less and vector closed-loop control

- Built-in EMC filter, logic programming and application functionality

- Fieldbus communications: Modbus, DeviceNet, PROFIBUS, MECHATROLINK-II, EtherCAT and CompoNet

- Regenerative solutions as option

- CE, cULus, RoHS

Ordering information