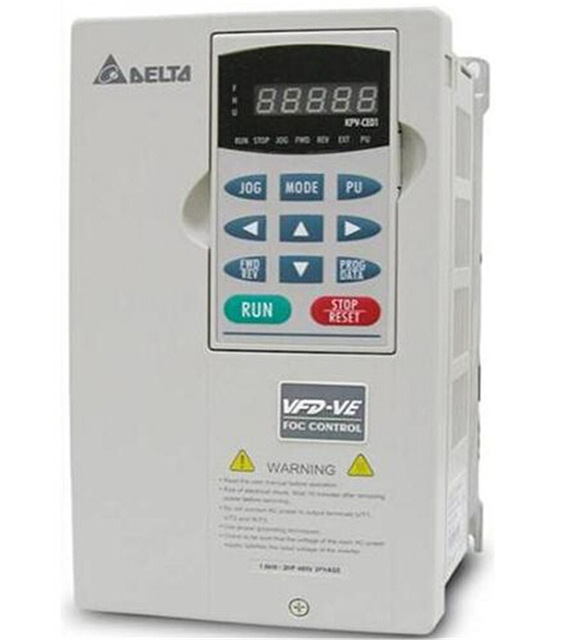

Inverter DELTA VE/VL/VJ SERIES

Features

This series adopts FOC (Field Oriented Control) which is a far more precise vector control algorithm. It can be used in both speed control and position control similar to a servo motor drive. The multi-function I/O terminal is expanded to meet users' various application needs. In addition, it is supplied with a Windows based PC software program for managing parameters and dynamic monitoring. It provides an excellent solution for load regulation. It can output 150% of rated torque at zero speed, and it can have "point to point" and relative distance control functions for position control, making it the best choice for challenging industrial control applications.

Specifications

-

Output frequency: 0~600Hz

-

4 points adjustable V/F curve, Sensorless Vector Control, Field-Oriented Control

-

Position/Speed/Torque control mode

-

Sensorless Vector Control 150% torque at 0.5Hz

-

150% holding torque with speed feedback

-

Overload : 150% for minute and 200% for 2 seconds

-

Rotational/Static Auto-tuning for the motor parameters and Auto-tuning for load inertia

-

Excellence torque limit in all 4 quadrants of operation

-

Dual RS-485 ports, Fieldbus and PC software tools for applications

Applications

Power transmission equipment, elevator, crane, CNC tooling machines, extrusion machines, injection molding machines, and auto-storage and retrieval systems.

VFD-VL Series

Delta's VFD-VL series AC motor drive designed for elevators are based on years' of experiences in designing AC motor drives, and the latest control technology adopted in VFD-VL will offer you high reliability and safety. All the features of VFD-VL are to meet the needs from the market, e.g. controlling the brake for motors, backup electricity, built-in brake loop, auto-tuning of motor parameters, numerous encoder interfaces, bountiful communication functions and self protection, etc.

-

Output frequency: 0.00 ~ 120.00Hz, offering output torque of more than 150% when at zero speed.

-

The vector control by FOC, enabling smooth and comfortable operation of the elevator.

-

S-curve acceleration/deceleration and battery for abnormal power shut-down.

-

Overload capacity: 150% of rated current for 1 minute and 200% of rated current for 10 seconds

-

Complied with EN954-1 (safety-relay) standard.

-

The built-in brake module saves you installation space and cost

-

Built-in with Modbus/CAN bus communication interface.

-

With optional LCD digital keypad and PC tuning software.

Home elevator, cargo elevator, passenger elevator, residential elevator and crane.

VFD-VJ Series

The Delta Hybrid Servo Drive VFD-VJ Series is designed with AC servo technology to drive hydraulic systems with perfect control of the drive, motor and hydraulic unit.

Specifications

- Field Oriented Control

- Suitable for both synchronous servo motors and asynchronous servo motors

- Built-in brake unit (up to 22kW)

- RS-485 communication interface (RJ-45) and standard MODBUS communication protocol

- Precise current detection for system protection with safety ensured

- New software for PC connection allows real time monitoring of AC motor drive status

Structure of a Hybrid Servo System

- When pressure and flow instructions are given to the injection molding machine, the Delta VFD-VJ series begins PID calculation simultaneously to attain the actual pressure and speed feedback data, and drive the servo motor and the hydraulic pump. The Delta VFD-VJ series offers you a system with fast response and high duplication accuracy.