Inverter DELTA C/CB/CP/CH SERIES

C2000 Series

The VFD-C2000 series is a high-level field oriented control AC motor drive with a high-performance variable-frequency technology, FOC control. It features versatile driving controls, modular design, wide variety of applications, easy maintenance, low malfunction rate, self diagnosis and competitive market price and brings customers not only the high-efficiency construction but also the most economic solution to compete with the global market.

Specifications

-

Speed/torque/position control mode, dual rating design (Normal duty/heavy duty)

-

Outstanding 4-quadrant torque control/limit

-

2 in 1 (induction motor and synchronous motor)

-

Built-in Delta PLC function, safe stop function and brake unit

-

Support of various network protocols

-

Synchronous position control

-

Long-life design and life detection of important components

-

Enhanced protections and adaptation to ambient conditions

-

Complies with global safety standards, including CE, UL and cUL

-

Modular design for easy maintenance and many extensions

-

High-speed communication interface with built-in CANopen and MODBUS communication (optional cards for PROFIBUS-DP, DeviceNet, MODBUS TCP and EtherNet/IP)

CP2000 Series

Delta's Sensorless Vector Control Drive CP2000 Series has extended the idea of energy saving and uses this principal as the basis of its design. The CP2000 is specifically designed for applications such as air blowers, pumps and HVAC drives with its intelligent PID control providing the greatest efficiency. The Sensorless Vector Control (SVC) offers timely response to load torque increase/decrease which satisfies customer requirements for load changes while enhancing motor performance. A 3-step V/F curve response is used in the variable torque environment to adequately adjust the input voltage and attain the greatest overall performance; this function is especially helpful in pumps and fans applications. It also includes additional functions for operation and protection in variable load environments, such as flying starts, auto-acceleration/deceleration, momentary power loss restarts, auto-tuning, and more. The CP2000 series provides you with the ultimate energy-saving solution for your applications.

Specifications

-

With a built-in 10K steps Delta PLC allows user to execute distributional control and independent control when connecting to a network system. Delta CP2000 series drives provide you the intelligent control possibility beyond your imagination.

-

The calendar function allows user to program the PLC procedure, the ON/OFF in chronological order, the daylight saving time and etc.

-

A wide range of models (0.75~400KW) to fulfill the demands of different industries.

-

The modularized design eases the maintenance and expansion.

-

High speed communication interfaces with MODBUS protocol and BACnet protocol built in. Diverse communication methods to satisfy clients@@ needs on multi-controls. So the following options are available for you: the ProfiBUS-DP, the DeviceNet, the MODBUS TCP, the Ethernet-IP and the CANopen Cards.

-

Long-life design and self diagnosis for key components.

-

Special PCB coating design (Printed Circuit Board) for enhancing environmental tolerance.

-

Complied with global safety standards: CE, UL and cUL

-

Standard LCD model (IP20/NEMA1) with built-in PLC to support up to 10K steps

-

Excellent heat-sink design. Able to operate at 50°C ambient temperature and to adjust automatically rated output value to make the AC drive to work continuously.

-

Run fire mode while emergency to have uninterrupted smoke releasing and pressure adding

-

Multi pumps control at fixed amount, fixed time circulating control. Able to control 8 pumps at the same time. (Such as Image01 and Image02, optional multi-control relay card is required.)

CH2000 Series

Using new drive technology, Delta presents you with its next generation CH2000 Series AC Motor Drive. Providing high performance with robust design the CH2000 is equipped with a larger starting torque and high overload capability to fulfill the needs of heavy load and impact loading applications.

Specifications

Super Heavy Load (SHD)

- Overload ability: rated current of 150% up to 60 seconds, 200% up to 3 seconds

- Starting torque: above 200% at 0.5Hz in normal conditions, up to 200% at 0Hz in FOC+PG mode

- Output frequency: 0.00~600.00Hz (for model above 90kW: 0.00~400Hz)

- Induction motor and synchronous motor control

- Built-in PLC program capacity: 10K steps

- Noise reduction

POWERFLEX 40/40P

- Power ratings:

- 100...120V: 0.4...1.1 kW / 0.5...1.5 Hp / 2.3...6 A

- 200...240V: 0.4...7.5 kW / 0.5...10 Hp / 2.3...33 A

- 380...480V: 0.4...11 kW / 0.5...15 Hp / 1.4...24 A

- 500...600V: 0.75...11 kW / 1...15 Hp / 1.7...19 A

- IP20 NEMA/UL Type Open, plate drive, flange mount, IP66 NEMA/UL Type 4X/12, and DIN rail

- Optional IP30 NEMA/UL Type 1 conversion kit

- Ambient temperatures up to 50 °C (122 °F) permitted with minimal spacing between drives

- Zero Stacking™ Drives for ambient temperatures up to 40 °C (104°F)

- V/Hz and sensorless vector control, as well as process PID

- Integral RS-485 communication

- Optional serial converter module for use with any controller with DF1 messaging

- Optional DeviceNet™, ControlNet™, and EtherNet/IP™, Profibus DP, BACnet™, and LonWorks® communication modules

- Drive overload protection, ramp regulation, and flying start

- StepLogic® allows operation as an independent position controller

- Configuration and programming via integral LCD keypad, remote keypad, or software

- Premier Integration with PowerFlex® AC drives uses the Logix control platform to simplify parameter and tag programming and reduce development time

Packaged Drive Options

- Power options include circuit breaker, fused disconnect, bypass, and input fuses

- Output relay and transformer control options

- Door-mounted human interface module (HIM), hand/off/auto selector switch, status pilot lights, and speed potentiometer

PowerFlex® 40P AC Drives provide closed-loop control with an option for Category 3 Safe Torque-off in a compact and cost-effective design. This drive is designed to meet global OEM and end-user demands for flexibility, space savings and ease of use. It is a cost-effective solution for speed or basic position control of applications such as diverters, smart conveyors, packaging machines, and fiber-spinning machines.

- Power ratings:

- 200…240V: 0.4…7.5 kW / 0.5…10 Hp / 2.3…33 A

- 380…480V: 0.4…11 kW / 0.5…15 Hp / 1.4…24 A

- 500…600V: 0.75…11 kW / 1…15 Hp / 1.7…19 A

- IP20 NEMA/UL Type Open, plate drive, flange mount

- Optional IP30 NEMA/UL Type 1 conversion kit

- V/Hz control, sensorless vector control, as well as process PID

- Internal RS-485 and Common Industrial Protocol (CIP) communication

- 4-digit display, 3 additional status indicators and scroll/reset button

- Optional Remote Human Interface Modules (HIM) or PC interface for programming

- Speed control with and without encoder feedback

- Drive overload protection, ramp regulation, and flying start

- Fiber application-specific features

- StepLogic® allows operation as an independent position controller

- Configuration and programming via integral LCD keypad, remote keypad, or software

- Premier Integration with PowerFlex® AC drives uses the Logix control platform to simplify parameter and tag programming and reduces development time

Available Safety Options

- Safe Torque-Off option is certified at PLd/SIL2 Cat 3

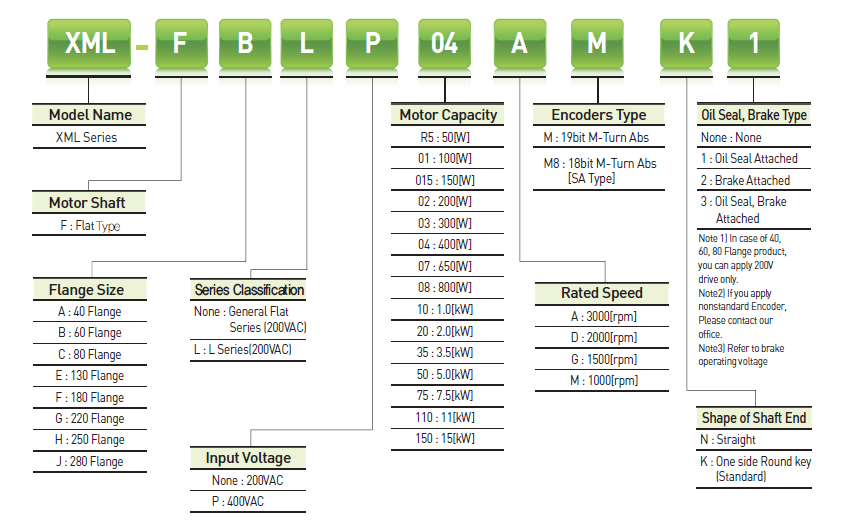

Servo LS XML MOTOR

User-oriented XGT Servo systems complete your optimal solution. Your motion systems visualize the perfect solution though the LS comprehensive product ranges for the optimal drives and applications. Its high-performance vector, precision and speed control are user-friendly and cost effective.

อินเวิร์ทเตอร์ที่เหมาะสมกับงานประเภท (Heating, Ventilating and Air conditioning) ซึ่งให้ความสำคัญกับเรื่องการประหยัดพลังงาน เหมาะสมกับทั้ง ปั๊มน้ำ พัดลม และ Chiller ซอฟท์แวร์และฟังก์ชั่นการทำงานถูก ออกแบบให้เป็นเรื่องง่ายๆสำหรับทุกคน

Supply voltages and power range

3 x 200-240 V...............................1.1-45 kW

3 x 380-480 V..........................1.1-1000 kW

3 x 525-600 V..............................1.1-90 kW

3 x 525-690 V...........................1.1-1400 kW

Low harmonic drive

3 x 380-480 V...132-710 kW

12-pulse drive

3 x 380-500 V...250-1000 kW

3 x 525-690 V...250-1400 kW

Features and benefits

- Slim down your TCO. Ongoing demands for lower TCO are challenges the VLT® HVAC Drive can help you meet.

- Install it outdoors in extreme climates. Searing heat and deep frost are all in a day’s work for the enhanced VLT® HVAC Drive. You get full reliability running this drive outdoors with temperature extremes from 50°C to minus 25°C.

- Control multiple IE5 PM motors. Bring energy efficiency to a new level in your fan and pump applications. You can even control multiple IE5 permanent magnet (PM) motors using only a single drive.

- Save time. You can parameterize and troubleshoot the drive from outside the AHU, thanks to the remote LCP. Maximize uptime by reducing the shutdown, since there is no need to open up the AHU and lock it down again afterwards.

- Get the freedom to choose your favorite motor. Choose exactly the motor you prefer, for whatever reason from supply security to performance optimization. The enhanced VLT® HVAC Drive is not only optimized to control induction, permanent magnet and synchronous reluctance motor technologies; our development team is working all the time to include compatibility with upcoming motor technologies in future software updates as well.

- Get the freedom to communicate. The ability to integrate the AC drive easily into your building automation system is a key to optimal control. The VLT® HVAC Drive features a number of HVAC-specific communication protocols, such as BACnet/IP, that give you flexibility of installation in both new and existing building automation systems.

Applications

Pumps, fans, compressors.

PC tools

VLT® Motion Control Tool MCT 10

VLT® Motion Control Tool MCT 31

Danfoss ecoSmart

Danfoss HCS (Harmonic Calculation Software)

Danfoss Servo Sizer

VLT® Energy Box

CONTACT US

|

FOSTER ENGINEERING CO.,LTD 84/212 Moo.12 Suwinthawong Rd.,Sansab Minburi Bangkok 10510 Thailand

Call center: 0-2989-4867 Fax : 0-2989-4867 Tel : 089-114-2595 , 081-174-1901 082-459-3693 Email : This email address is being protected from spambots. You need JavaScript enabled to view it. |

|

|

! Working Time : Monday - Friday 8:00 - 17:00 ! |

|